Call (304) 744-7871 | Request A Quote

Model L Weld Sight GlassAssembly Instructions

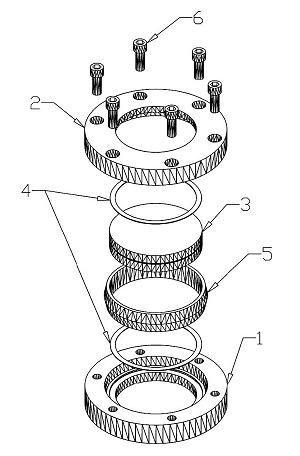

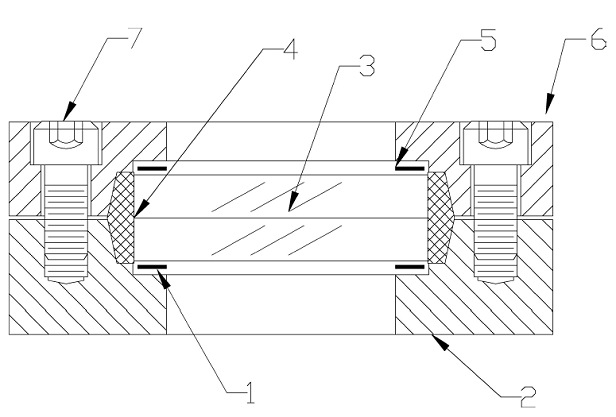

This unit was assembled for shipment and the cap screws (7) were purposely not tightened. Before installation, the sight glass unit should be disassembled by removing the cap screws (7), cap (6), lens (3), seal (4) and cushion gaskets (1 & 5). Replace only the cap (6) and tighten the cap screws (7). The cap (6) will help prevent the body (2) from warping during the welding process. Use an appropriate welding procedure to minimize distortion of the body. After the body has been welded and cooled, follow the instructions below to reassemble the unit. INSTALLING PARTS:

|

Process Equipment Catalog

Support & TrainingCompany Info & Resources

< Home |

MADE IN THE USA

4540 W. Washington St. Charleston, WV 25313

(304) 744-7871 | Fax (304) 744-6705 | Privacy Policy

(304) 744-7871 | Fax (304) 744-6705 | Privacy Policy