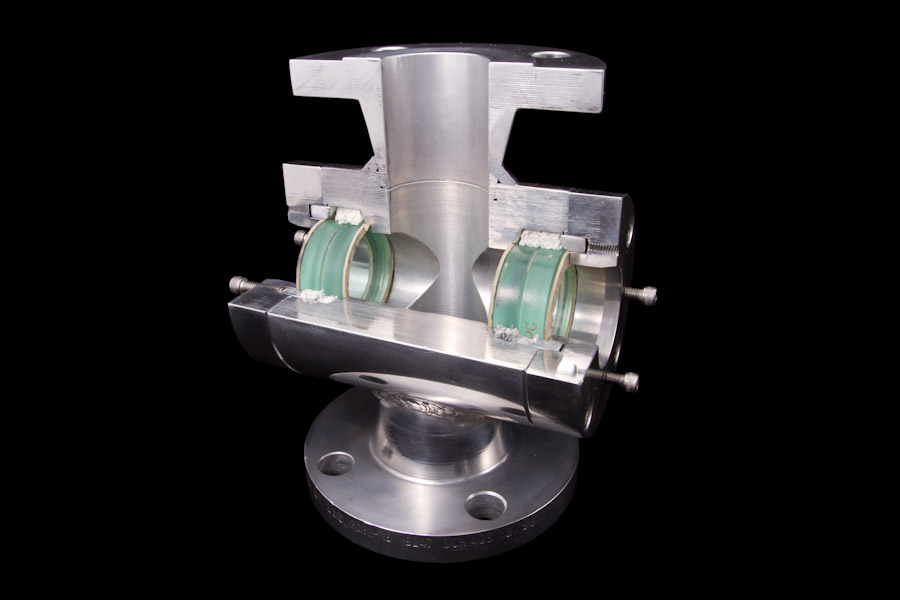

Model B Safesite Sight Flow Indicator

Description:

The Model B SafeSite is an in-line (See-Thru) type that is used in exising or new piping to observe material flow through a line. This unit employs standard ANSI B16.5 (2" to 8") flange ends to specified face-to-face dimensions and can be supplied with indicators such as drip tubes, rotors or flappers. The Model B SafeSite can be manufactured to meet your pressure and temperature requirements, and different materials of construction are available to meet your process needs. Other connections are available upon request, including stub-end with lap joint flanges, buttweld, threaded, or sanitary. These units can be adapted to meet smaller or larger-size flange connections if necessary.

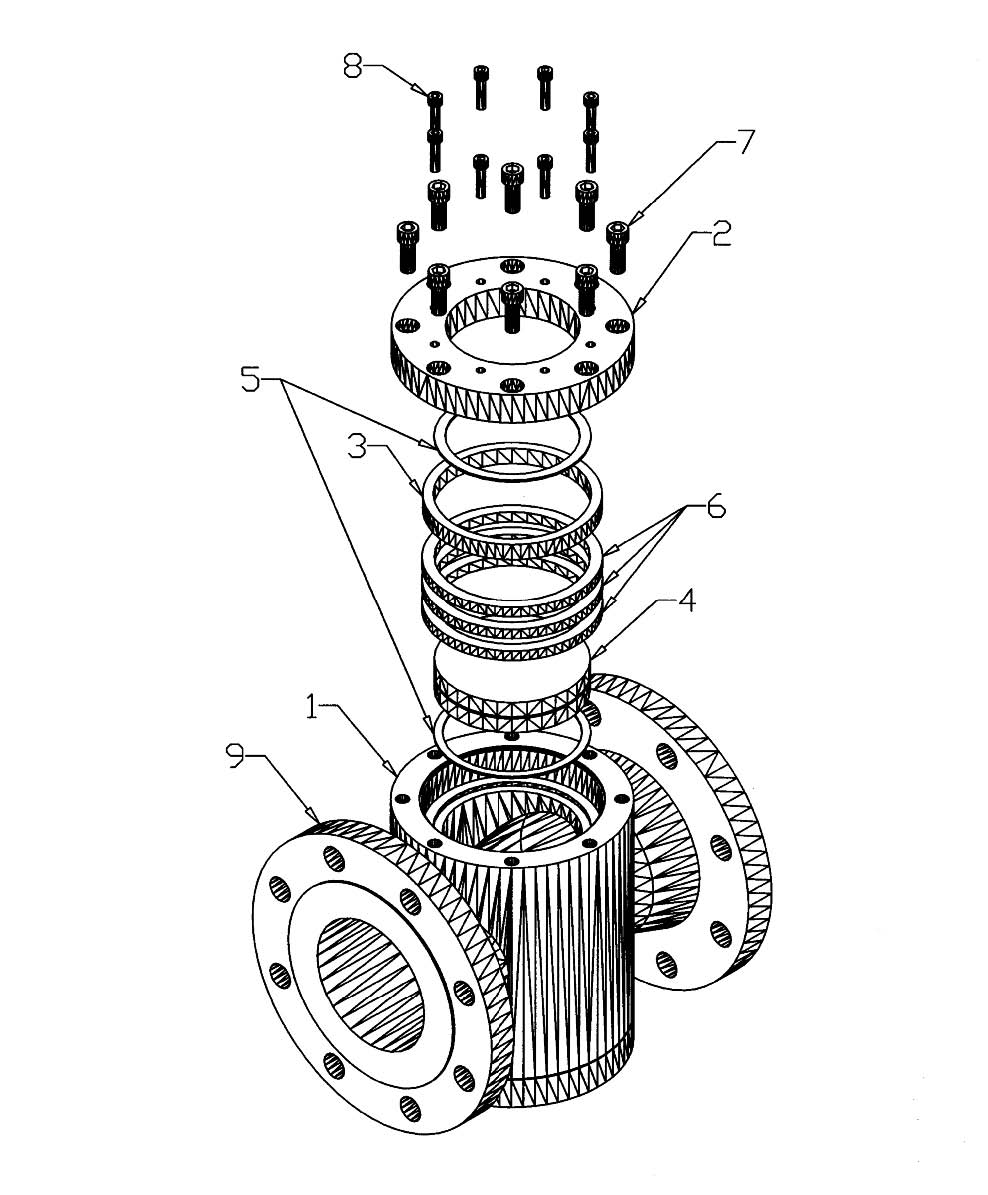

Materials of Construction:

- Body: 316 or 304 Stainless Steel SA- 351; Carbon Steel SA-519; Hastelloy; Alloy 20; Titanium; Aluminum; etc.

- Retainer Caps: 316 or 304 Stainless Steel SA-351; Carbon Steel SA 519

- Compression Rings: 304 Stainless Steel SA-351; Carbon Steel SA-519

- Lens: Two-Piece Laminated Tempered Soda Lime (Standard); Tempered or Annealed Borosilicate; Quartz; Lexan; Acrylic; Mica Shields

- Lens Cushion Gaskets: Teflon® (Standard); Grafoil®; Gylon®; Blue-Gard®; etc.

- Lens Packing: Combination Teflon® Impregnated and Viton® (Standard); Graphite; FDA Teflon®; etc.

- Retainer Cap Bolts: 18-8 Stainless Steel; Carbon Steel SA-193

- Compression Screws: 18-8 Stainless Steel; Carbon Steel SA-193

- Flanges: 316 or 304 Stainless Steel SA-182; Carbon Steel SA-105; Hastelloy; Alloy 20; Titanium; Aluminum; etc.

|

|||

| This sight glass has been certified as maintaining a Quality Assurance System in accordance with the Pressure Equipment Directive 97/23/EC (PED) Annex I, Paragraph 4.3 by the Certification Body 0036 of the TÜV Industrie Service GmbH. |