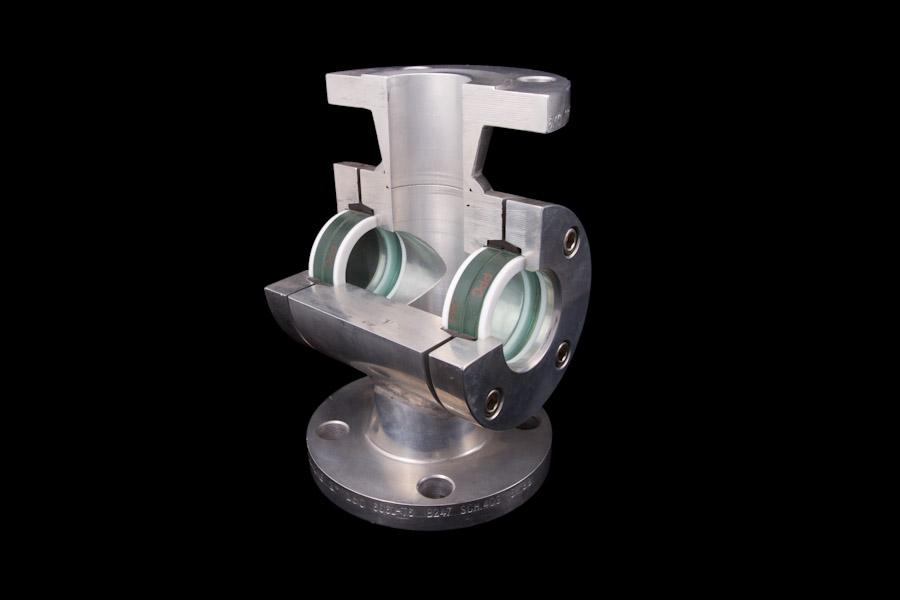

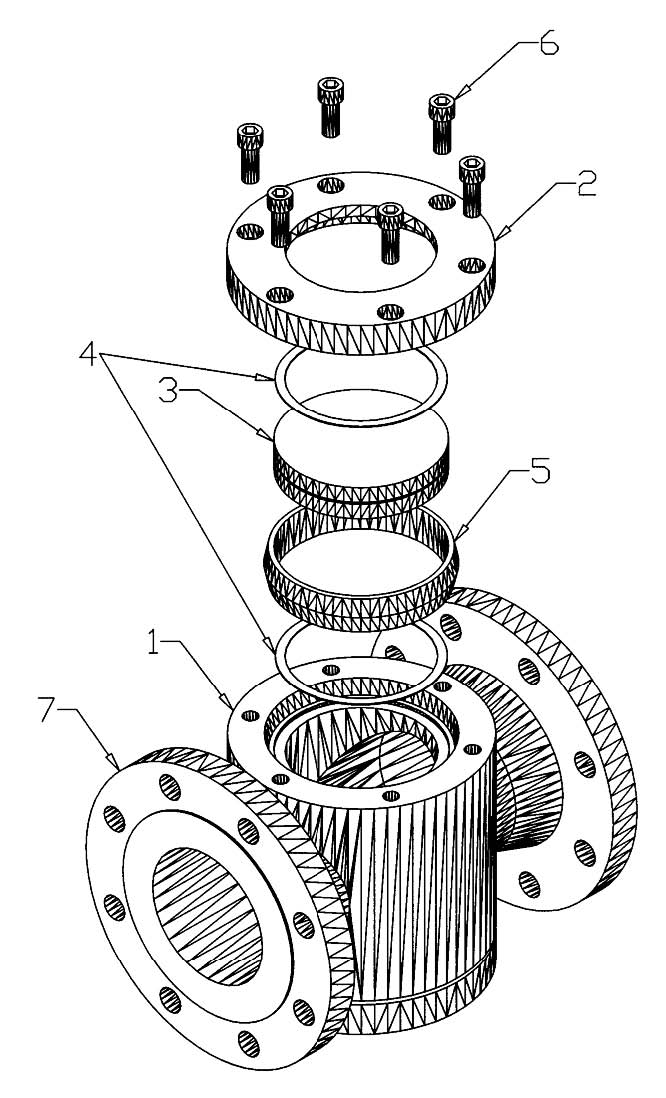

Model L Safesite Sight Flow Indicator

Description:

The Model L Safesite is developed to satisfy the need for pressure requirements from full vacuum to 100 psi while still providing the safety of PresSure Products higher-pressure units. This unit is an in-line (See- Thru) type that is used in existing or new piping to observe material flow through a line. It employs standard 150 psi ANSI B16.5 (2" to 8") flange ends to specified face-to-face dimensions. Model L Safesites can be supplied with indicators such as drip tubes, rotors or flappers, and rated for temperatures up to 450ºF. The unit can be provided with Silicone, Viton®, Teflon® or EPDM seals. Different materials of construction are available to meet your process needs, and other connections are available upon request including stub-end with lap joint flanges, butt-weld, threaded or sanitary. Units can be adapted to meet smaller or larger-size flange connections if necessary.

Materials of Construction:

- Body: 316 or 304 Stainless Steel SA-351; Carbon Steel SA- 519; Hastelloy; Alloy 20; Titanium; Aluminum; etc.

- Retainer Caps: 316 or 304 Stainless Steel SA-351; Carbon Steel SA 519

- Lens: Two-Piece Laminated Tempered Soda Lime (Standard); Tempered or Annealed Borosilicate; Quartz; Lexan; Acrylic

- Lens Cushion Gaskets: Teflon®; Grafoil®; Gylon®; Blue-Gard®; etc.

- Seals: Teflon®; Viton®; Silicone; EPDM; etc.

- Retainer Cap Bolts: 18-8 Stainless Steel; Carbon Steel SA-193

- Flanges: 316 or 304 Stainless Steel SA-182; Carbon Steel SA-105; Hastelloy; Alloy 20; Titanium; Aluminum; etc.

|

|||

| This sight glass has been certified as maintaining a Quality Assurance System in accordance with the Pressure Equipment Directive 97/23/EC (PED) Annex I, Paragraph 4.3 by the Certification Body 0036 of the TÜV Industrie Service GmbH. |